EMMEDI supplies a full line of products to the tube, pipe and wire industries.

EMMEDI induction heating solutions for the tube & pipe industry are fast and efficient choices: from vacuum tube welders to solid-state welders and the new SiC (Silicon Carbide) technology, EMMEDI is still leading technological advancements in the market.

In addition to welder systems, Emmedi has also increased competences and skills in the design and manufacture of customized solutions for seam annealing and in-line bright annealing equipment. In-line heating systems complete the full range of products line.

Other processes offered are coating, upsetting and swaging.

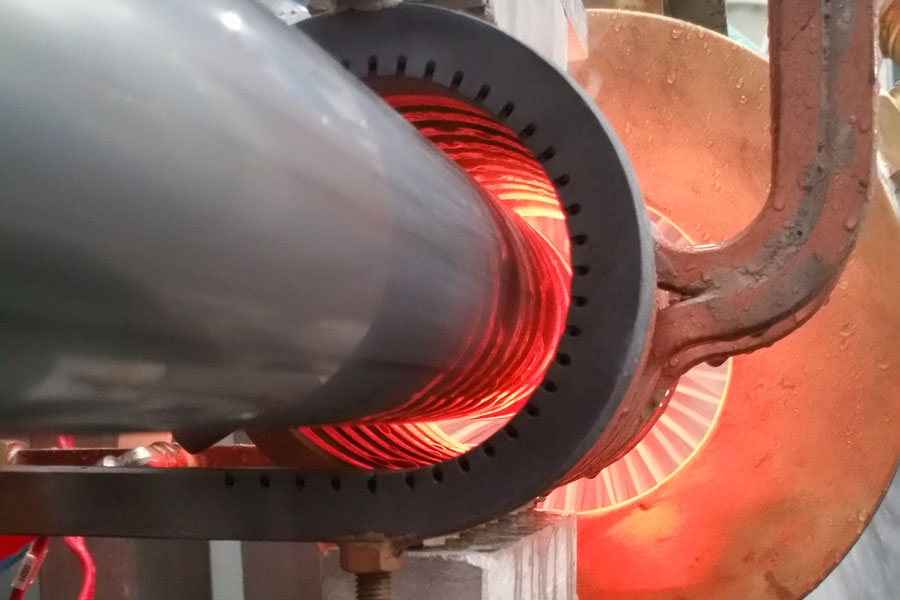

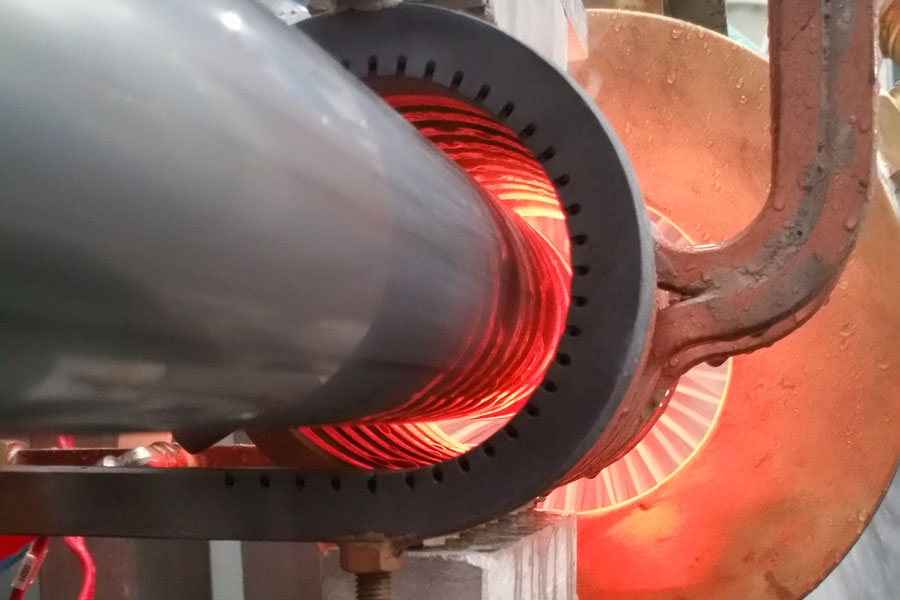

With a solid affiliation within the Ajax TOCCO group of global companies, EMMEDI can offer extended global solutions by using hot bending and stress relieving processes. Induction heating is anyway the preferred heating method for bending larger thick-walled pipes used in the chemical and power generation industries.

The team of skilled engineers and the know-how based on more than 60 years of experience, led EMMEDI to the development of a highly customized system that innovates technical approach to stainless steel for both seamless and welded tubes production.

Discover

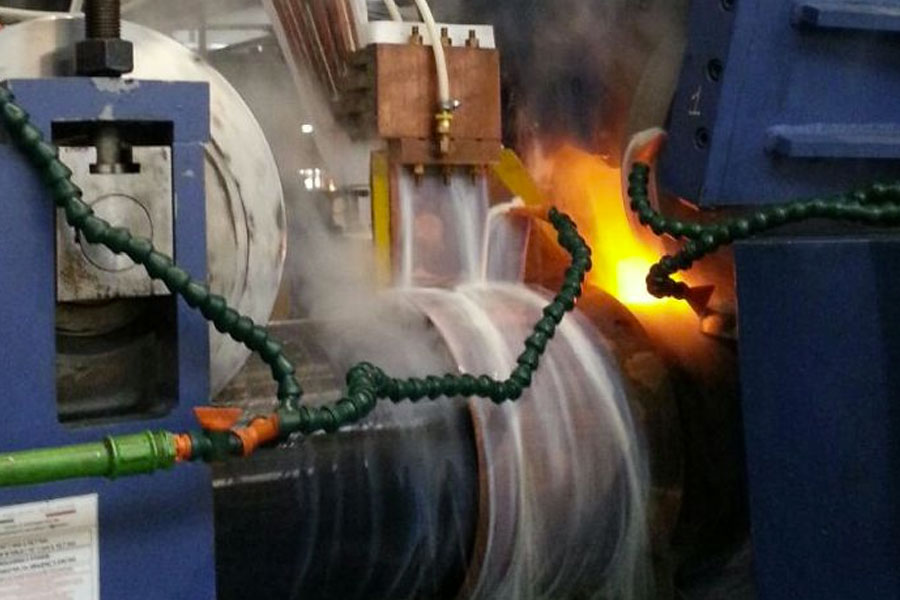

The in-line bright annealing process is mainly used with AISI 300, AISI 400, duplex, superduplex and titanium pipes for various application such as petrochemical, furniture, automotive, food and beverage.

Discover

The seam annealing process is dedicated to the normalization of the Heat Affected Zone (HAZ).

In many cases the welding line must be annealed after the welding process to prevent a failure point and provide a uniform metallurgical results.

The in-line process is mainly used for various applications such as petrochemical, furniture, automotive, food and beverage

Discover

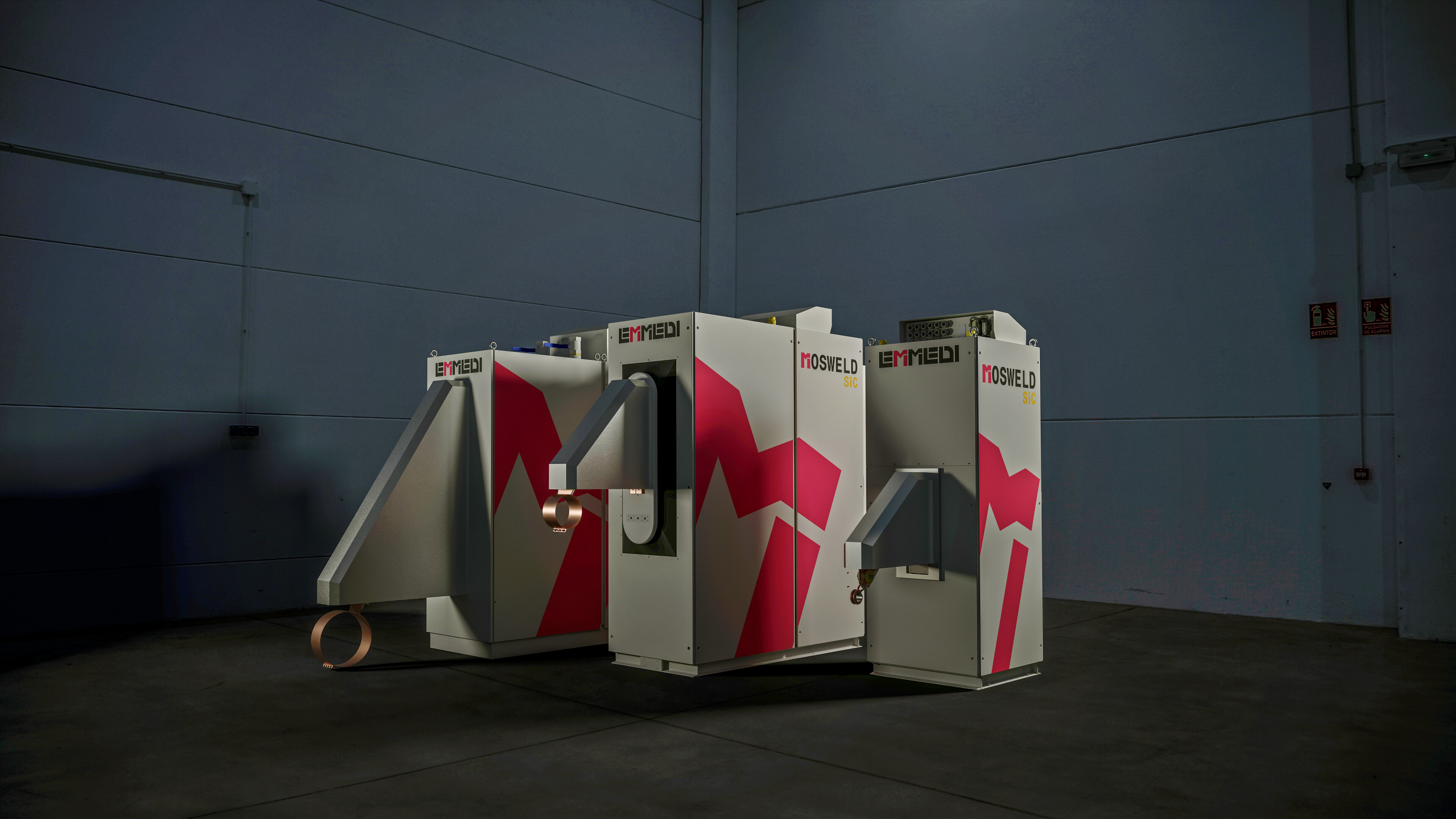

Mosweld is the ultimate solid-state power supply using MOSFET transistor technology, the highest overall enery efficiency (more than 90%) in the market allowing a decrease in production costs and an increase in reliability.

.

With a very good customers reference world-wide, the High Frequency Vacuum Tube is the “Classic” Welder, appreciated by the Tube industry throughout the decades for its extremely robust design and strong reliability.

Discover

Variable output frequency is a strategic choice when welding stainless steel tubes or pipes with a severe range of wall thickness and OD.

Discover

MOSWELD SiC is the ultimate solid-state power supply using Silicon Carbide transistor technology, the highest overall energy efficiency in the market allowing a decrease in production costs and an increase in reliability

Discover

Our goal is to continously improve your induction system

Discover