SAET EMMEDI Process Development Laboratory provide expertise in the development of Induction Heating and Heat Treatment.

New processes and innovative solutions are constantly evaluated by the PreDesign team and tested in the Process Development Lab: this is the core of the induction heating design process.

SAET EMMEDI laboratory and process development department provide expertise in the development of induction heating and heat treatment.

SAET EMMEDI LAB is the core of the R&D, where engineers test all the variables of the induction heating to obtain the desired profile.

Furthermore we set up inductor design and development services for custom inductors. We can perform preliminary test to verify heat treatment on parts with our own lab machines:

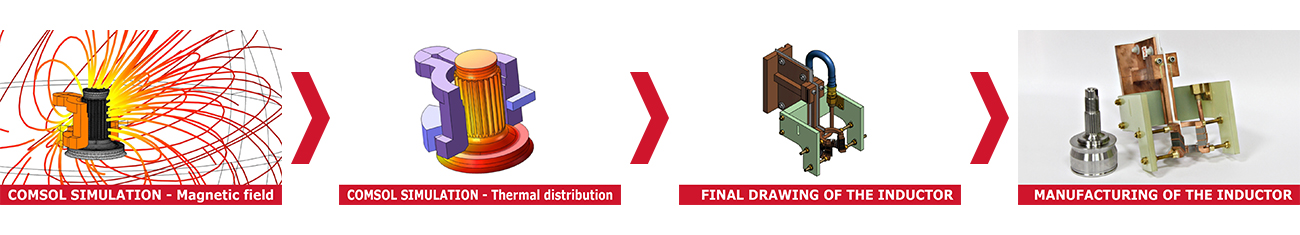

The preliminary design is an essential step for choosing the correct way to develop an inductor. Our company develops its innovative solutions, based not only on the great deal of experience gained in fifty years of activity, but by also utilizing up to date and modern practices in virtual simulations.The lab has experienced engineers coming from different fields of modern technology and they use software such as ELTA, COMSOL and FLUX.

The preliminary design follows rules and a business strategy that can be summed up in three simple steps:

All the collected data are carefully discussed and only after this analysis, will an initial inductor be manufactured for testing to verify part patterns and subsequently a production ready inductor will be produced.

Process Development