Advanced designs, Industry 4.0, and a wide range of power and frequencies are a few of the benefits of the SAET EMMEDI brand of power supplies.

SAET EMMEDI develops power supplies to meet the requirements of the different markets and act without compromises in terms of quality, reliability, dimensions and power reserves. The power solutions are designed for stand alone processes and to be integrated into an automated production systems. Advanced designs, Industry 4.0, and a wide range of power and frequencies are a few of the benefits of the SAET EMMEDI brand of power supplies.

AN INDUCTION POWER SUPPLY IS MORE THAN A RANGE OF FREQUENCIES AND POWER FOR APPLYING INDUCTION HEATING.

The right selection of a converter makes possible a long-lasting investment performing as the first day, a reliable induction process, flexibility in the application, energy savings, low maintenance and easy operation. A power supply must allow you to focus on your business.

ROBUST DESIGN AND MATERIALS

SERIES COMPENSATED POWER SUPPLIES

PARALLEL COMPENSATED POWER SUPPLIES

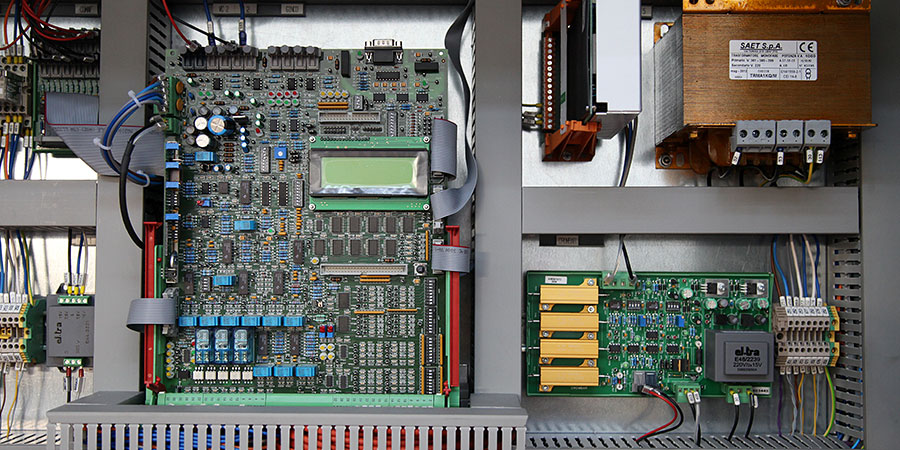

ICoS, which means flexibility and integration, is a compact power supply designed to be integrated into an automated production system, where induction heat treatment with power up to 20kW is required. ICoS can be installed inside an electrical cabinet It has been engineered in order to be integrated inside an electrical cabinet with the same simplicity as an electric drive, in case heat treatment of the pieces is required.

Liquid cooling (if available in the host equipment) or forced air, small size (300 x 350 x323mm.), connectivity and ease of use are the cornerstones of the flexibility of ICoS. Three-phase power feeding and + 24V (in addition to the fluidic cooling equipment, if provided for) are the only electric inputs necessary for ICoS: it will be sufficient to connect the suitable inductor to the power output – directly or through a transformer … and the generator will be ready for use.

The compact power supply inside the host system is managed with an ethernet cable via fieldbus (PROFINET or Ethernet IP). For more flexibility, it is possible a direct management from the browser, via web server or via external digital analog I/O. ICoS is Industry 4.0 compliant.

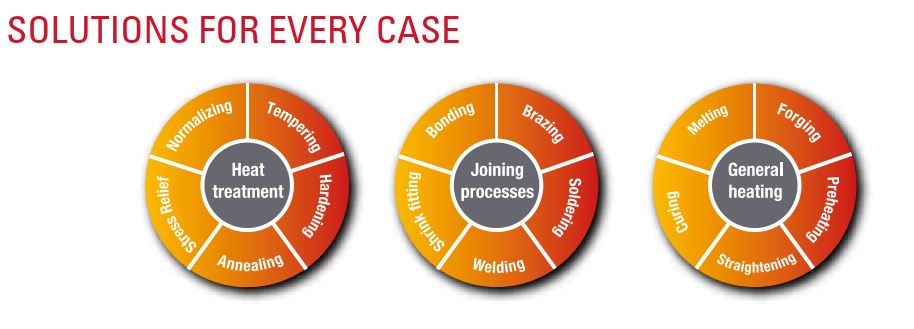

The automotive and electromechanical industries as well as the household appliances industry, are just some of the areas in which ICoS can be easily integrated: preheating, brazing, hot assembling, shrink fitting, annealing are some of the various treatments that ICoS can efficiently manage inside complex production processes.