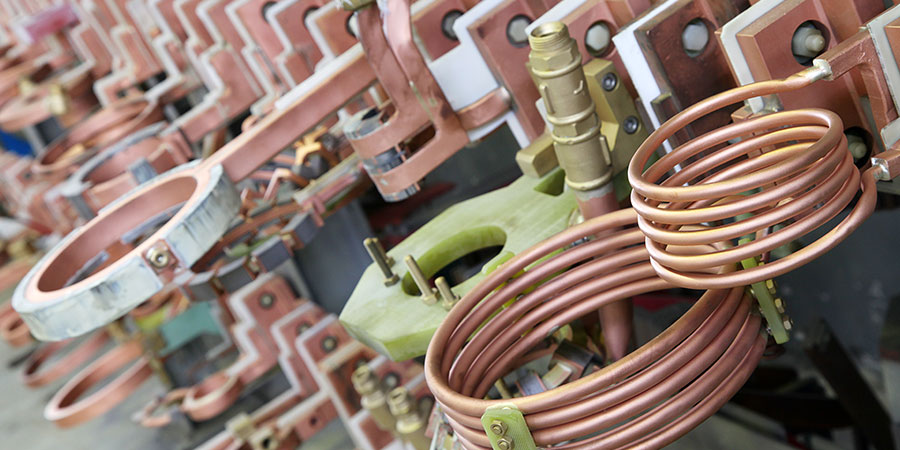

The coil is the heart of every induction heating machine

The coil is the heart of every induction heating machine. Each inductor is specifically designed to reach the desired hardening pattern of a mechanical component.

SAET EMMEDI can design and manufacture all kind of inductors upon request

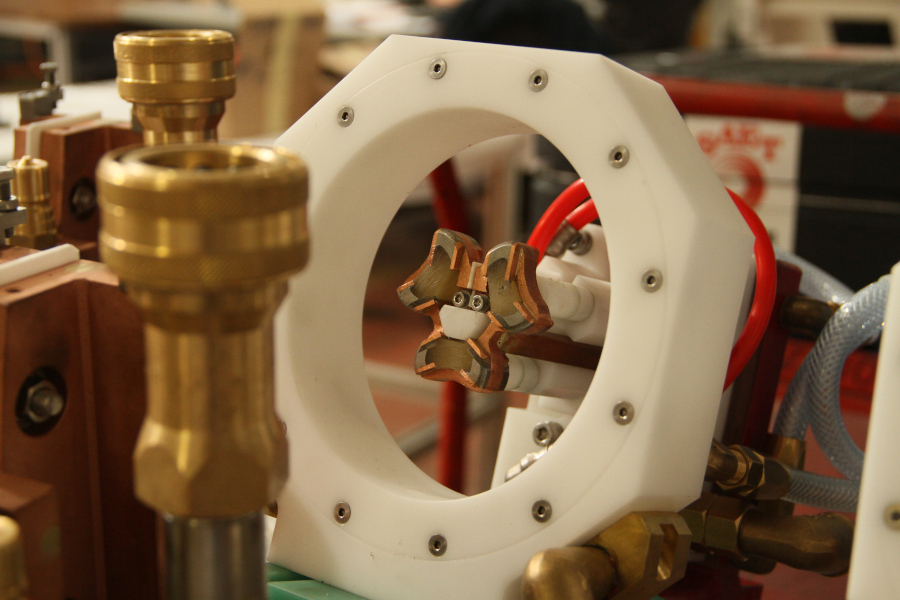

Tempering inductors are designed to reheat the hardened part by increasing the toughness. Compared to the traditional tempering system, induction tempering can shorten time with temperature control and process traceability in a in-line solution.

Single shot, tunnel, or scanning: tempering inductors can have a wide range of design to cover all the parts shape and requirement.

SAET can design and manufacture all kind of tempering inductors upon request.

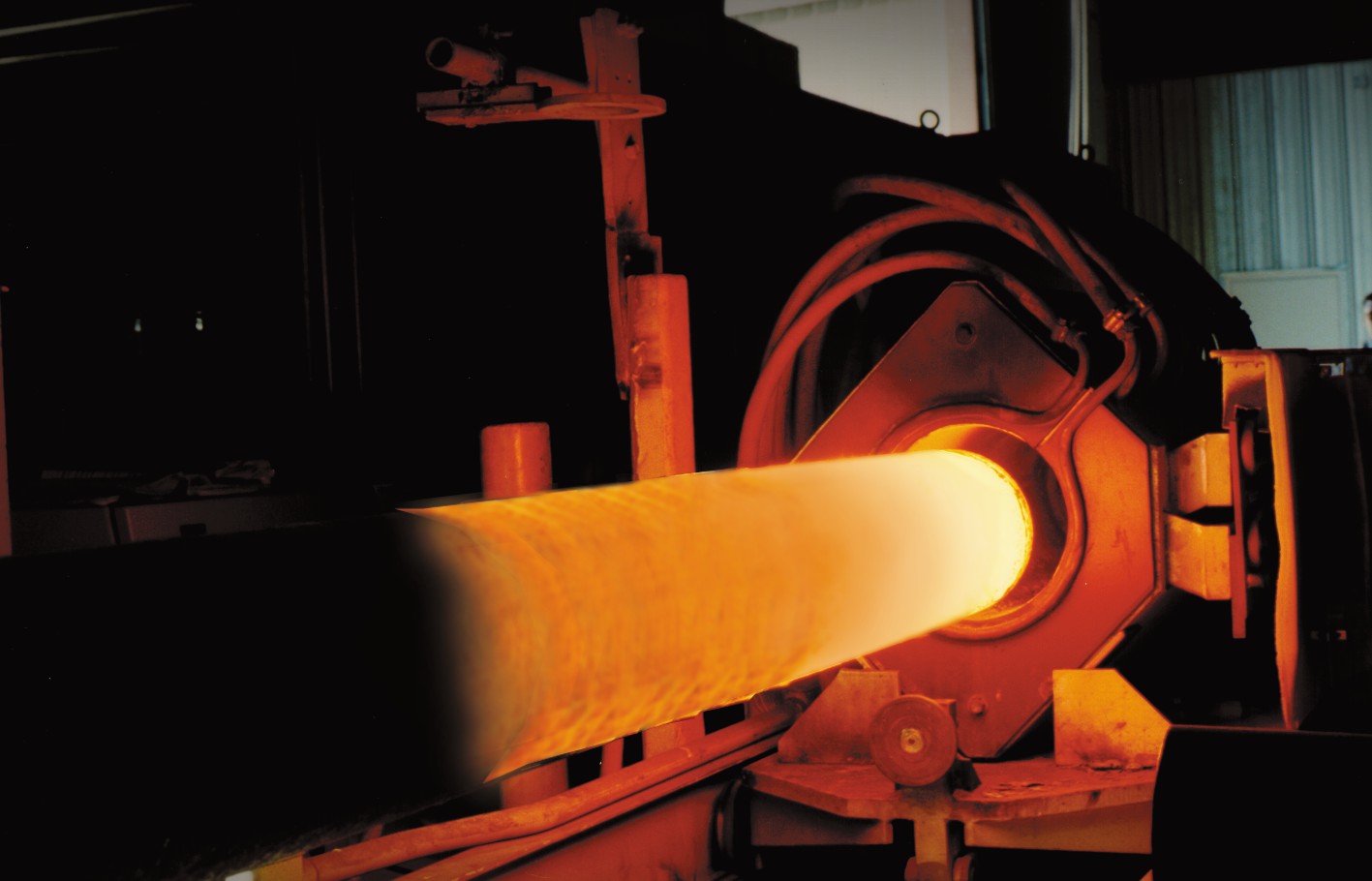

Induction forging systems ensure a very high efficiency, higher product quality with less scales and scraps, less maintenance and a higher flexibility.

Forging coils are built with different materials and design according to production type and requests. Partial or continuous heating, steel or brass elements, refractory material or ceramic tubes, modular or specific design.

SAET can design, build, service and repair all forging coils.

Tube heating coils are designed for specific applications and enhance the overall processes by increasing flexibility and optimizing energy consumption.

All tube heating inductors are tailor-made according to customers needs and requirements.

SAET EMMEDI utilizes a 3D printing technology for coils applications, reducing set-up time, guaranteeing higher dimensional accuracy and precision, with higher process reliability.

The only use of refractory in an induction system is in the coils. With the benefit of long coil life in a SAET induction system, refractory repairs and relining area greatly minimized. Die life is also extended with the drastic scale reduction.

SAET offers an extensive computerized inventory of factory certified replacement parts for our induction heating and melting equipment to assure quick turn around.

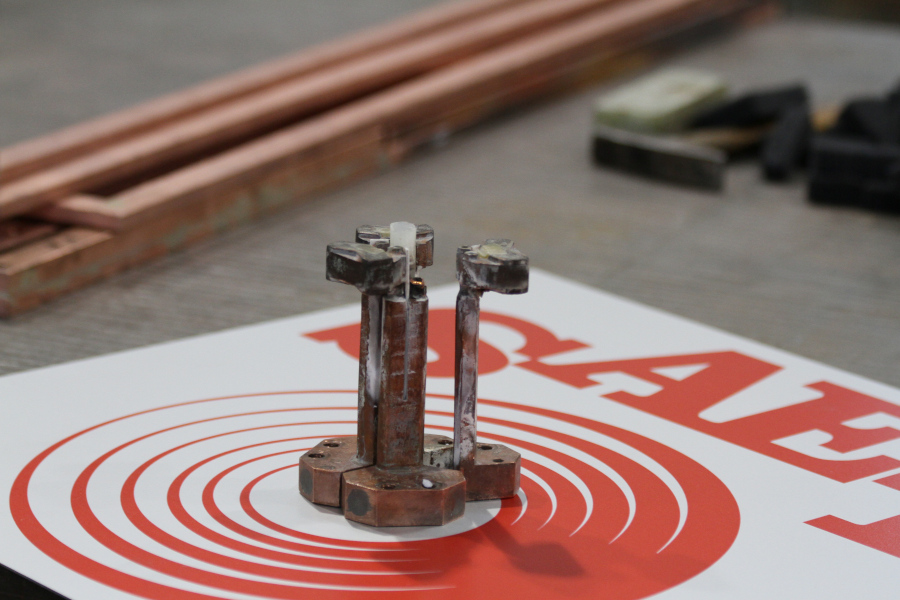

Gli induttori sono il cuore degli

impianti di trattamento termico ad induzione.

Quando

arrivano usurati o danneggiati, gli esperti professionisti del reparto

induttori mettono a servizio dei clienti la loro

esperienza e, in tempi rapidi e con grande

abilità, utilizzando macchine utensili all'avanguardia e

materiali di qualità, forniscono il miglior servizio di riparazione e di

miglioramento del design.

Questi

sono i passaggi che vengono attentamente eseguiti, per renderli nuovi:

PULIZIA/SABBIATURA – COSTRUZIONE

PARTICOLARI RAME (SU FRESE CNC) – SALDATURA SPIRA – SECONDA SABBIATURA – AGGIUNTA

LAMIERINI – MESSA IN DIMA E COLLAUDO GEOMETRICO E FLUIDICO

Gli induttori vengono poi spediti a

destinazione nelle valigette antishock in modo da garantire un imballaggio

sicuro e resistente agli urti.

Per richieste di riparazione induttori

contattate: globalservicehd@saetemmedi.com

o i seguenti numeri +39 335 7724846 -

+39 335 328863 - +39 346 4792439