Production Monitoring System

INDUCONTROL is the quality system and complete solution for real-time process and traceability monitoring, specifically designed for induction heat treatment equipment.

This system is a key element to prevent faults.

The new XRATEPLC is a smart board specifically designed by Saet Emmedi for data acquisition and connected to machine fieldbus.

It acquires any signal through optical fiber connection and it is integrated with the automation field bus.

A flexible system

As a versatile and flexible system:

Discover more here

CMS 4.0 is an hardware module linked to SAET frequency converters.

It is designed to increase their connectivity and computational power.

Main features and key points of CMS 4.0 in industry 4.0 framework are:

– PROFINET fieldbus connection for NC / PLC and related HMI

– Ethernet connection makes available a web interface

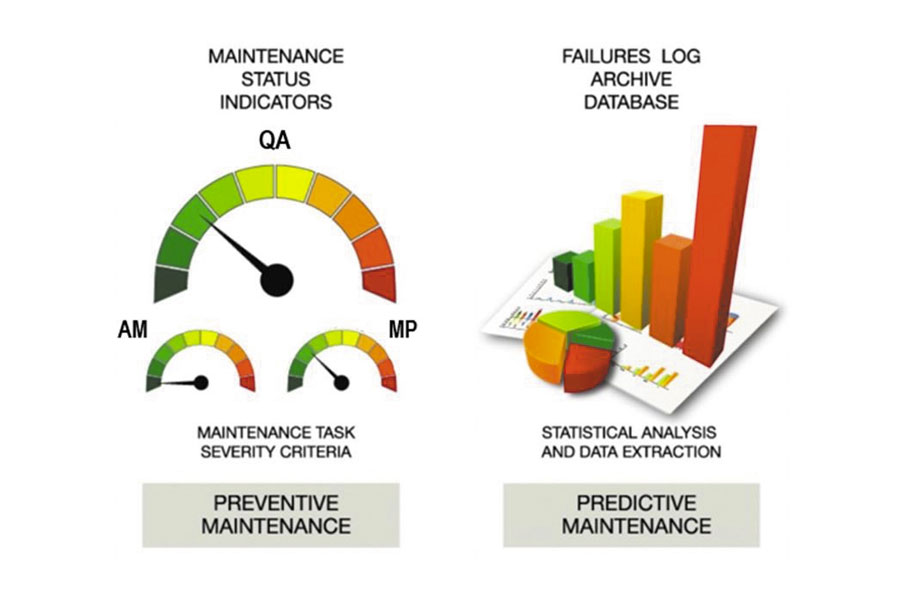

– Alarm statistics are available for predictive maintenance

– User-friendly web interface for diagnosis

SAET frequency converters are network connected.

Advantages of PPM

Lower downtime

→ higher machine availability

Less “quick fix” maintenance

→ cost reduction

Different people, same actions

→ higher process quality

Method (systematic, organized)

→ compliance with Quality Standards

(audits, customer policies…)

A breakthrough in knowledge sharing with the use of augmented reality devices, Saet Reality is the ultimate experience of remote guidance, where on-site maintenance, troubleshooting and production restoring take place by means of an industrial tablet, connected with SAET HQ in voice and video, capable of overlay hand and tools, movements on screen, text chatting, screenshots and video recording. SAET best-in-class field service is now instantaneously available, reducing time of analysis, enhancing first-time fix ratio, leading to major savings thanks to reduced downtime.

The remote system allows our engineers to communicate with SAET systems through modem or wireless network. This technology provides real time analysis of equipment located at our customer’s facilities.

Technicians can control the process to apply proper adjustment according to production requirements.

Telephone service helps the user get back into production, often without the need for field service assistance. Whenever field service is required, we will dispatch one of our district service engineers to quickly get your system up and running again.