With a very good customers reference world-wide, the High Frequency Vacuum Tube is the “Classic” Welder, appreciated by the Tube industry throughout the decades for its extremely robust design and strong reliability.

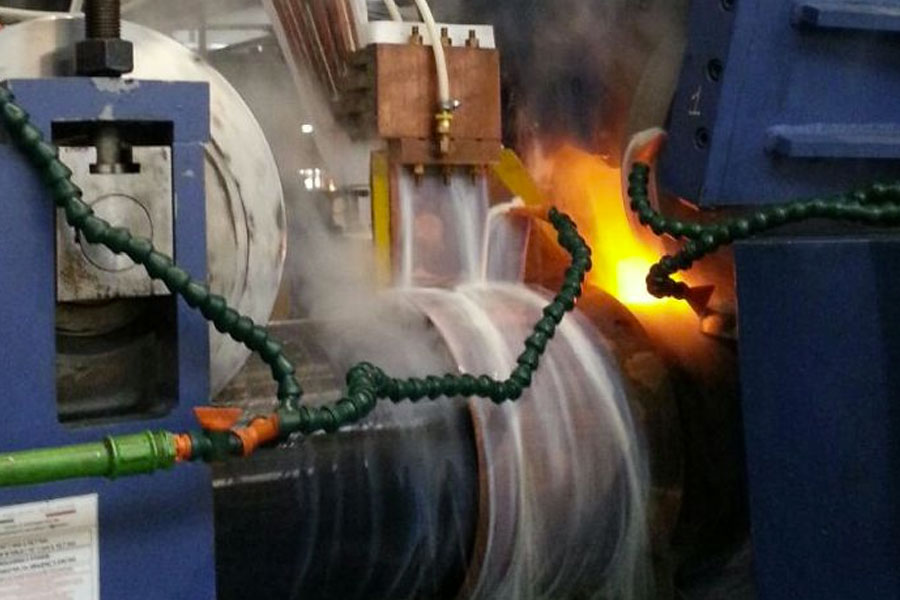

With very good customer references world-wide, the High Frequency Vacuum Tube is the “Classic” Welder, appreciated by the Tube industry throughout the decades for its extremely robust design and strong reliability. Having an overall efficiency around 70%, it is provided with a patented Ripple Filter granting less than 1% of residual ripple. The unique advantage of HF Classic Welders is the extremely compact welding head, composed by a small cabinet containing the output transformer and the capacitors.

50 - 1200 kW

0 - 100%

150 - 850 kHz

On demand

By Thyristor Control automatic voltage regulator: ± 1% at Net variation ± 10%

Less than 1% at any power output

Water to water by Stainless Steel heat exchanger

27°C

Light grey RAL 7035

The Automatic High Frequency Welding Head Adjustable Table has been designed to hold the welding head next to the tube mill. The support is equipped with three motorized movement controls along axes X, Y and Z, and allows the operator to accurately position the inductor directly from the Welder Control Desk. Maintenance and production changes are therefore easier and faster. As an alternative to standard alphanumeric touch-screen panel, a specific software running on an industrial PC, installed on the control desk, has been developed. The Welding Management System allows for a real time check of all main welding functions and internal storage for all welding parameters and events. Working data that is stored can be used to repeat the best welding performances or to analyze events in the recipes database.

SAET EMMEDI customers can benefit from the resources of a global corporation. We provide worldwide assistance through our network of regional sales and services engineers.