The team of skilled engineers and the know-how based on more than 60 years of experience, led EMMEDI to the development of a highly customized system that innovates technical approach to stainless steel for both seamless and welded tubes production.

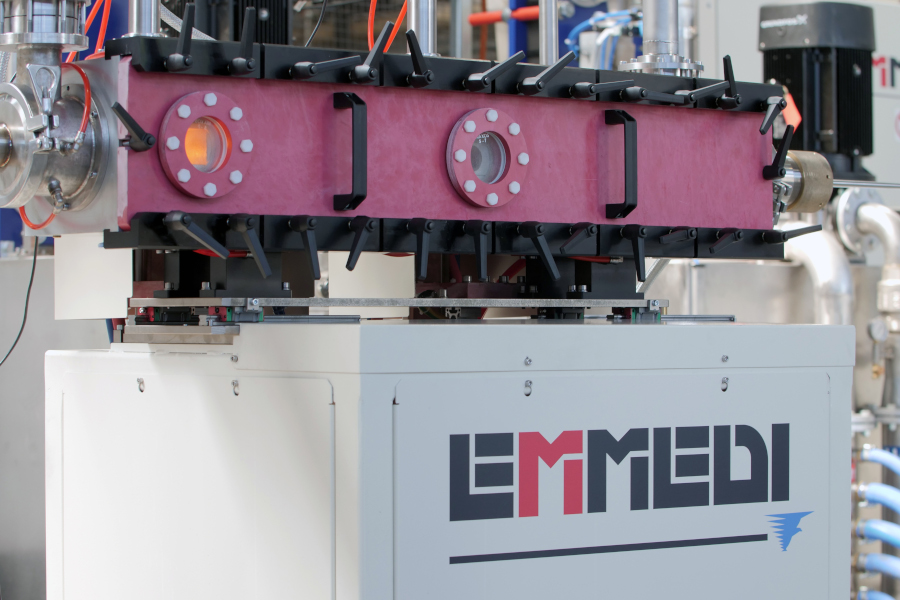

The EMMEDI brand is recognized worldwide for over 60 years and supplies a full line of products to the bar, tube and wire industries: complete coating systems, in-line bright annealing as well as the seam annealing equipment, the full body heaters, the quenching and tempering systems that meet the most challenging market requirements.

The in-line bright annealing process is mainly used with stainless steel, duplex, super-duplex and titanium pipes for various applications such as petrochemical, furniture, automotive, food and beverage.

The team of skilled engineers and the know-how based on more than 60 years of experience, led EMMEDI to the development of a highly customized system that innovates technical approach to stainless steel for both seamless and welded tubes production.

Induction heating applied to this process reduces start-up times to a minimum and permits a power density higher than the conventional furnaces with a consequent reduction of the heating section, combined with a high quality in terms of metallurgical characteristics of the treated material.

To achieve brightness and hardness required by the annealing process, non-recycled pure hydrogen gas at a low rate is used for a perfect cleaning of tube surface in safety condition.

The outgoing hydrogen is burned to prevent gas dispersion in the environment.

SAET EMMEDI customers can benefit from the resources of a global corporation. We provide worldwide assistance through our network of regional sales and services engineers.