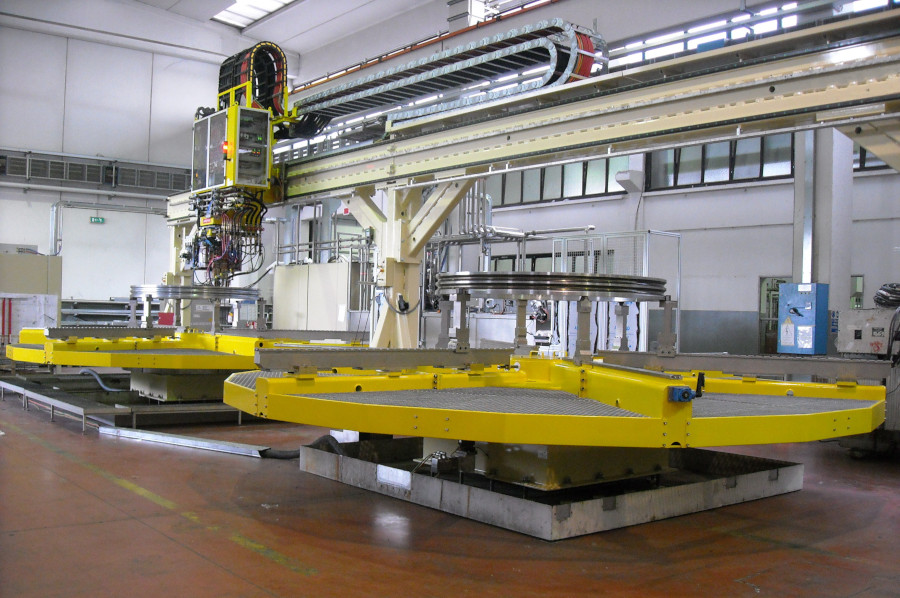

Double Horizontal Machine for Slewing Bearings

SAET PROVIDES TO ITS CUSTOMERS A PROVEN PROCESS KNOW-HOW FOR THE HARDENING OF RINGS AND GEAR

Key features of SAET horizontal machines are the advanced control of the coupling distance

between the part and the coil, the automatic or semi-automatic centering device, the possibility

to have two fully independent heating heads, and the accurate control of the quench flow to minimize part distortion.

The capability of SAET machines currently installed in the field are for parts up to 9m in diameter and 30 tons in weight with single or dual table.

1 x 200 kW (Pre-heating) + 1 x 200 kW (Austenitizing)

2-4 kHz / 8-10 kHz / 12-14 kHz

up to 550 mm/min (raceways) / up to 700 mm/min (teeth)

H 100-250 mm / OD 1000-6000 mm / Weight up to 8 tons

30-70 mm

M10-M30

CNC rotating tables + CNC gantry crane

SAET EMMEDI customers can benefit from the resources of a global corporation. We provide worldwide assistance through our network of regional sales and services engineers.