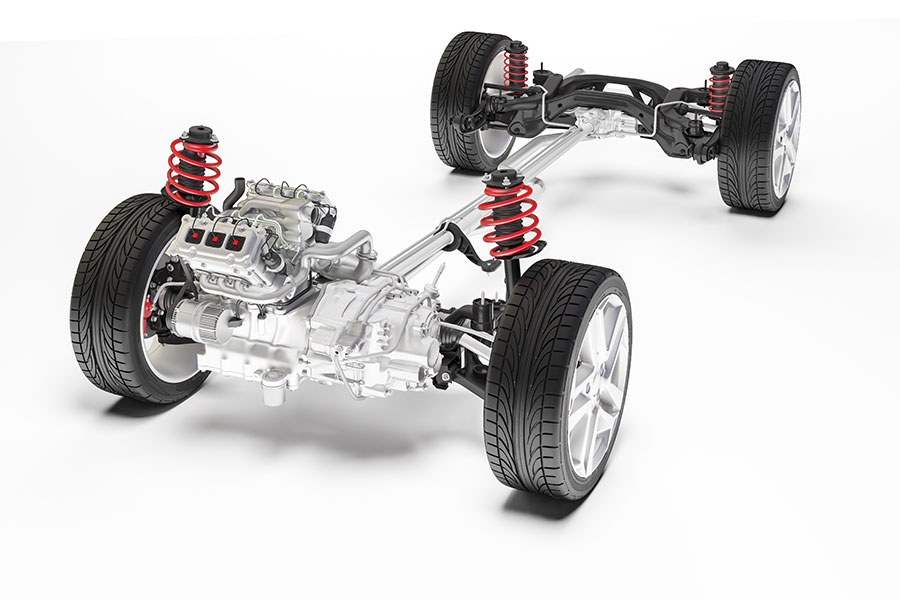

Induction Heating for Automotive Manufacturing. We understand the need for stringent heating performance that meets and exceeds the automotive industry’s tight tolerances.

Specific components:

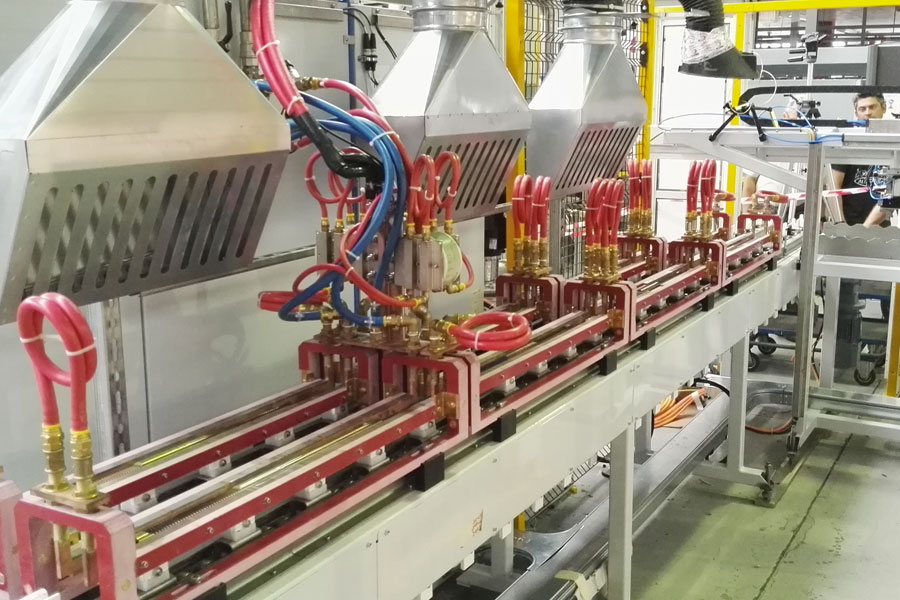

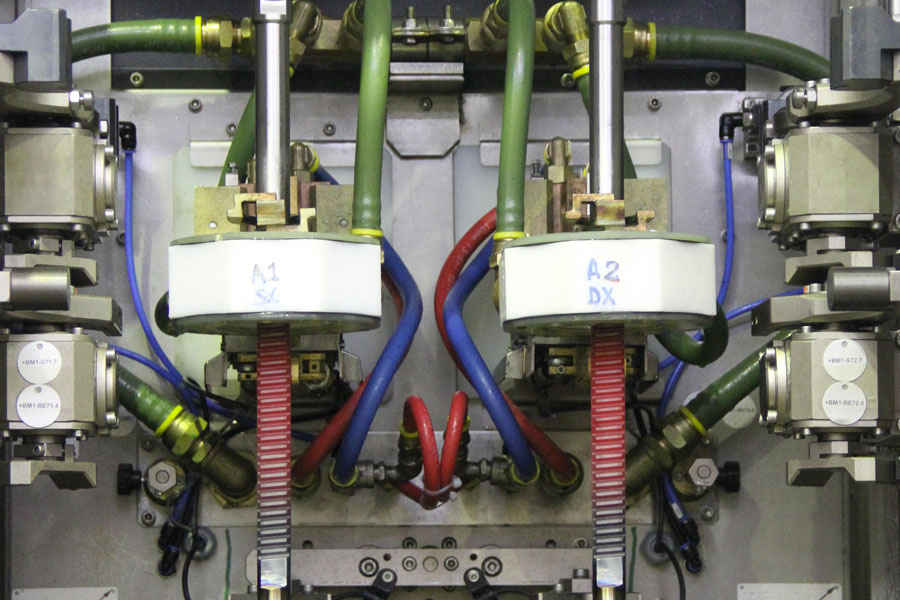

SAET is a strategic supplier of all major players in the automotive industry with a long and consolidated experience in the heat treatment of steering components.

Discover

SAET is a strategic supplier of all major players in the automotive industry with a long and consolidated experience in the heat treatment of steering components.

Discover

SAET is a strategic supplier of all major players in the automotive industry with a long and consolidated experience in the heat treatment of steering components.

Discover

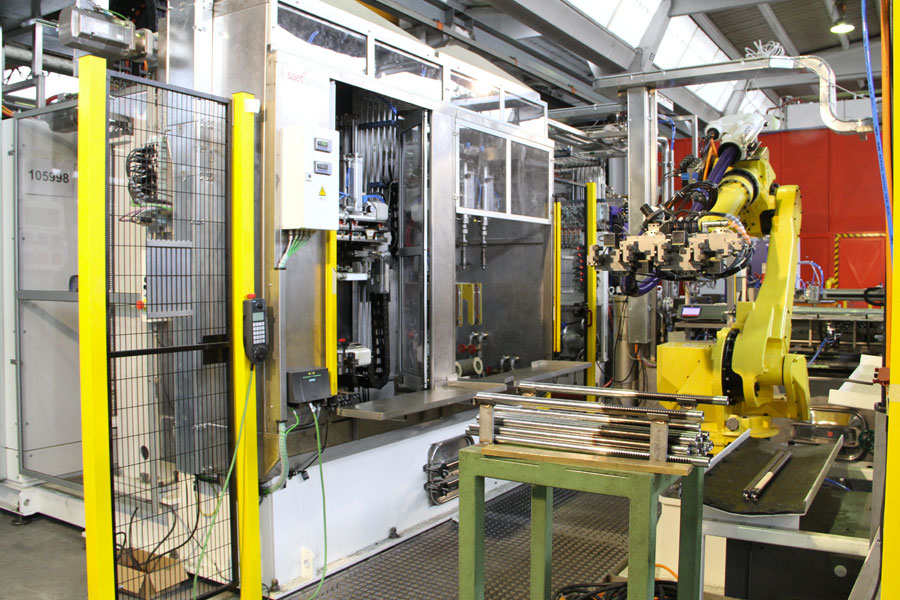

More than 300 machines manufactured since 1979

Discover

Our goal is to continously improve your induction system

Discover