How can Saet Emmedi help you in fulfilling your needs in an induction heat treat solution when approaching a new workpiece’s geometry and process requirement?

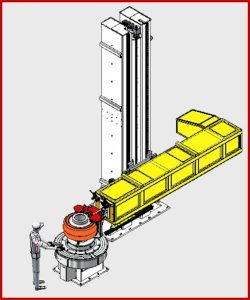

Here we can show an example of a challenging project Saet Emmedi is dealing with, the manufacturing of a 1 MW single shot hardener for a giant roller (900 mm of diameter, 500 mm of height) that requires more than 20 mm of hardening depth and whose hardening process is traditionally applied following other solutions instead of an induction approach.

Saet Emmedi develops its innovative solutions, thanks to the great expertise gained in more than fifty years of activity, but also with up-to-date and modern virtual simulations, thus reducing the times of process development.

The preliminary design to develop an inductor is an essential step that follows rules and a business strategy that can be summed up in three actions:

– Study and review of the specifications;

– Use of information from historical archives database;

– Virtual experimental approach.

All the collected data, after the electromagnetic analysis and the thermal and mechanical designs, are carefully discussed by Saet Emmedi’s skilled engineers to reach the best coil’s manufacturing, process and the whole machine design.

The preliminary design is then validated in the production and finally tested in our metallurgical laboratory to achieve the best outcomes and to meet the customer’s requirements.