For more than 30 years SAET EMMEDI has developed a highly recognized expertise in hardening solutions for gears, bearings and ultra large rings. A wide range of applications have been industrialized over the years with vertical and horizontal scanning machine configurations.

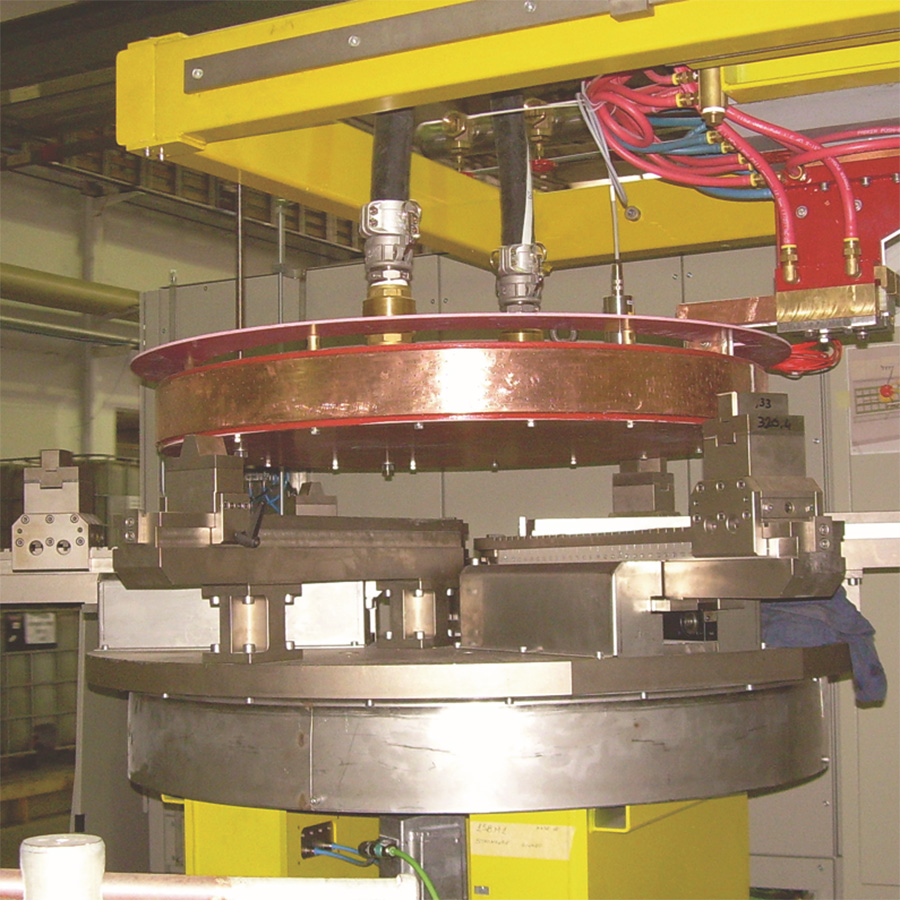

SAET EMMEDI has also pioneered high power single shot hardening machines up to 2500 mm diameter and 2500 kW power.

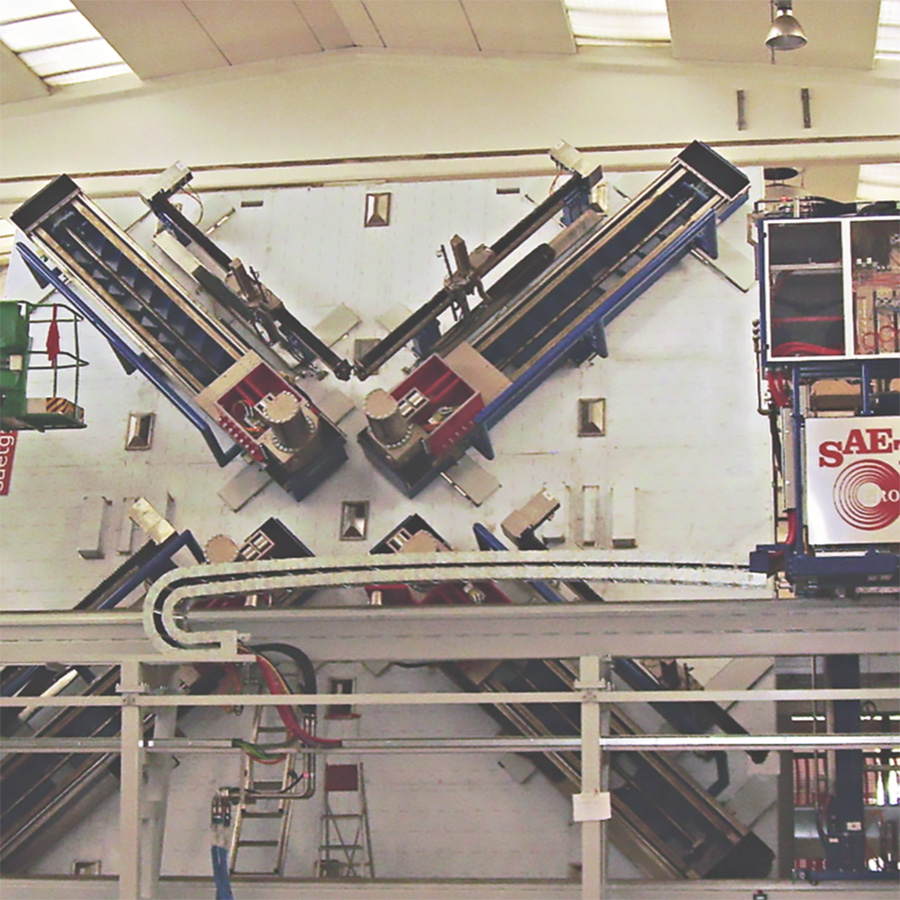

SAET EMMEDI’s seamless technology is the most innovative machine solution, able to scan harden large rings with the coordinated movement of 4 independent heating heads around the ring, without a soft zone.

Induction heating offers a convenient and

useful production solution for gears, bearings and ultra large rings hardening. Induction hardening can meet process

needs for a large range of gear and ring designs.

Induction

Technology is

eco-friendly and cost cutting: gas furnace replacement, reduction in carbon emissions, no heat up times, significant manufacturing cost savings from traditional methods.

SAET EMMEDI has pioneered high power single shot hardening machines with more than 30 years of experience on single shot hardening of large gears for both internal and external teeth, and installed capacity of up to 2500 mm gear diameter and 2500 kw of power.

SAET EMMEDI has introduced a seamless hardening solution for bearings and slewing rings thanks to the development of a patented scanning technology that eliminates the soft zone between start and stop locations on the rings.The outstanding metallurgical results, achieved by the installations already running, attest to the extraordinary possibilities of the patented SAET EMMEDI design.

Key features of SAET EMMEDI horizontal machines are the advanced control of the coupling distance between the part and the coil, the automatic or semi-automatic centering device, the possibility to have two fully independent heating heads, and the accurate control of the quench flow to minimize part distortion.

The capability of SAET machines currently installed in the field are for parts up to 9m in diameter and 30 tons in weight with single or dual table.

For raceway scan hardening, SAET EMMEDI inclined machines are a suitable alternative to the traditional horizontal solutions, allowing for better quench control for enhanced metallurgical characteristics

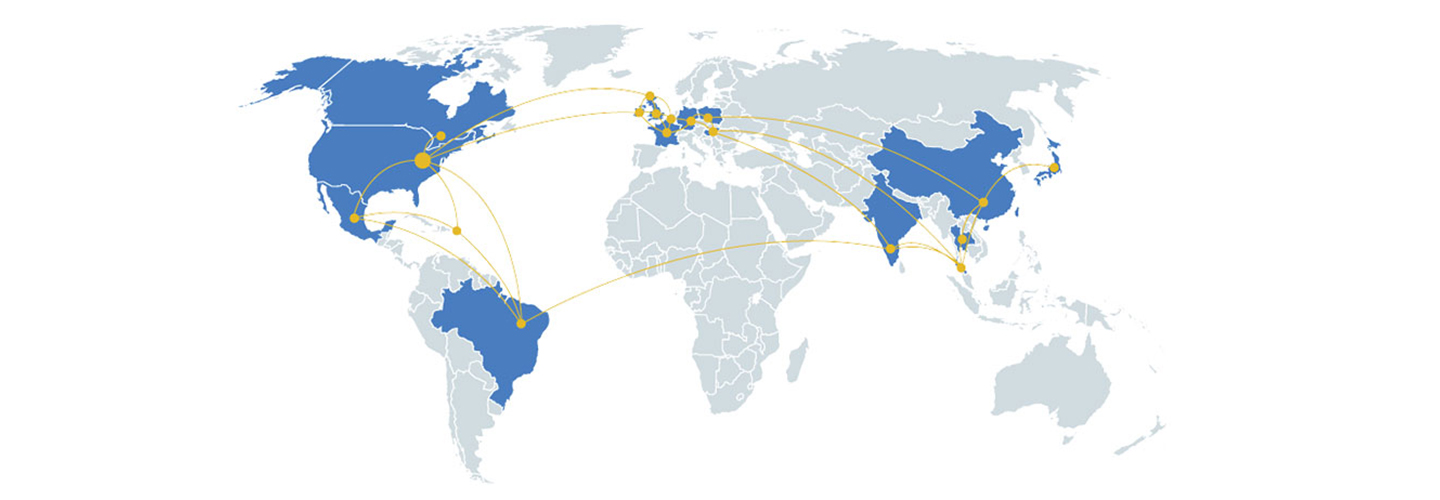

SAET EMMEDI, a wholly owned subsidiary of the American Park Ohio Industries, has more than 50 years of international experience, innovation and expertise in providing advanced induction applications for your industry.

SAET EMMEDI customers can benefit from the resources of a global corporation: the partnership of Ajax Tocco Magnethermic and SAET EMMEDI creates a steady presence in the market through widespread technical support, global solutions and after sales services from worldwide locations.

SAET EMMEDI laboratory & process development department provides expertise in the development of induction heating and heat treatment.SAET is the first supplier on the market to guide the customer through tailor-made process solutions.

SAET EMMEDI Lab is the core of R&D where the application engineers together with material scientists and metallurgists bring unparalleled capabilities to new process developments.

SAET EMMEDI Laboratory develops its innovative solutions from process analysis through development, but also with up-to-date and modern virtual simulations.

SAET EMMEDI laboratory and R&D continually invests in a wide range of machines, including a machine dedicated to process analysis and development of ultra large rings and bearings, thus ensuring the customer time and cost savings and providing a turnkey solution.